- Welcome to Libaijia

Get Neoprene Solutions for Your Industry Needs

Whether you need high-performance materials for diving, surfing, water rescue, hunting and fishing or water sports applications, our Neoprene solutions deliver unmatched quality and reliability.

Need Help

Our teams are ready to assist you in selecting the perfect neoprene material for your specific application. Contact us today for technical support, samples, or customized solutions!

Mail us for any Queries

Shimen County, Changde city, Hunan Province

We Are Here Always

008618665359936

Chat with us anytime

008613317360392

Toll Free & 24/7 Available

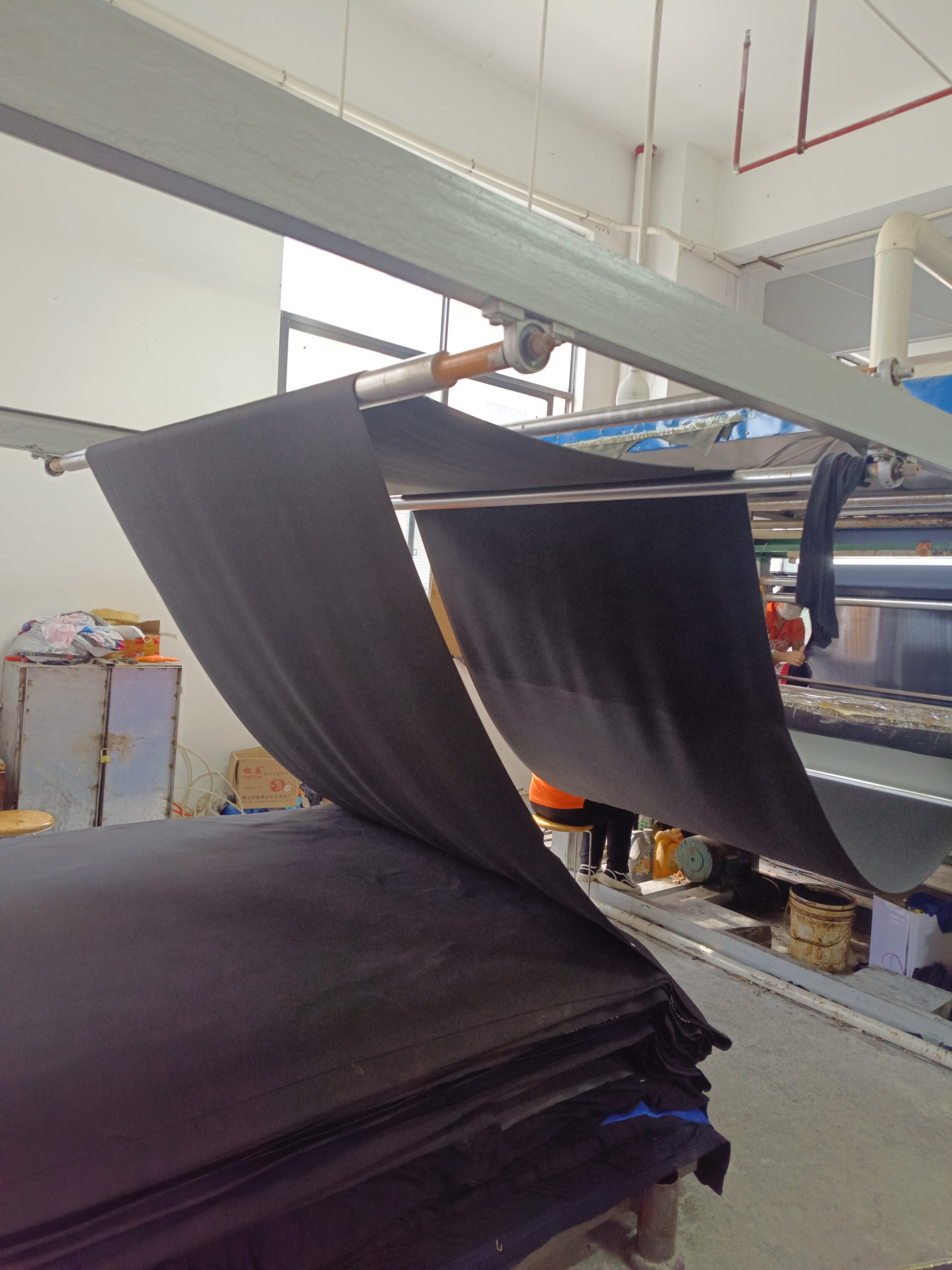

Laminated Neoprene Sheet

Laminated Neoprene refers to the process of bonding fabric to neoprene sponge surfaces using adhesive. This technique enhances the material’s: Surface durability (improved tear & abrasion resistance) Functional properties (inherits characteristics from the bonded fabric)

Key Features: Industry-standard processing method Customizable with various fabric types Maintains neoprene’s core flexibility

Common Fabric Options:

• Polyester (most cost-effective)

• Nylon (superior abrasion resistance)

• Lycra/spandex (maximum stretchability)

• more…

Primary Applications:

• Water Rescue Equipment

• Fishing & Hunting Gear

• Diving Equipment

• Pet Supplies

• more…

Neoprene Wetsuit Fabric Specifications:

Standard Width: 51″ (1.3 meters / 1.41 yards)

Shipping Notes: Samples: A4/A5-sized pieces available via express delivery

Bulk Orders: Shipped by sea freight for cost efficiency

Key Considerations:

• Low value-to-volume ratio makes air freight uneconomical

• Recommended for manufacturers/wholesalers rather than DIY projects

Bonded Neoprene Fabric - Manufacturer

Custom Neoprene Fabric Solutions

As a professional neoprene manufacturer, we expertly combine rubber sponges and fabrics sourced globally to create tailored materials for your exact needs.

Material Options:

▸ Premium Grade CR sponge + high-elasticity performance fabrics Superior stretch/durability for demanding applications

▸ Standard Grade SCR sponge + engineered fabrics Balanced cost/performance ratio

▸ Economy Grade SBR sponge + polyester fabrics Cost-effective for budget-conscious projects

Key Notes:

✔ Material cost variance is significant (CR:SCR:SBR ≈ 4:2:1)

✔ Strict quality control ensures true material composition

✔ Solutions tailored to your product positioning and budget

Frequently Asked Questions

Are you a direct manufacturer?

Absolutely, we had our own cutting machine,embossing machine, lamination machine, die cut machine, warehouse, floor shop.We can also pick up you inspect us.

Can you do OEM for me?

Of course.Just telling me what you thinking or send some of pictures of your sample, we will make the products you need.

How do you control the products quality?

We creat professional QC team in each step, which well control your goods quality during all the mass production till shipping time.We can do inspection service for you.

Can you provide Free sample and return the sample fee to us?

Of course free provide, sample fee can be refund base on the quantity.

_副本.png)