- Welcome to Libaijia

Get Neoprene Solutions for Your Industry Needs

Whether you need high-performance materials for diving, surfing, water rescue, hunting and fishing or water sports applications, our Neoprene solutions deliver unmatched quality and reliability.

Need Help

Our teams are ready to assist you in selecting the perfect neoprene material for your specific application. Contact us today for technical support, samples, or customized solutions!

Mail us for any Queries

Shimen County, Changde city, Hunan Province

We Are Here Always

008618665359936

Chat with us anytime

008613317360392

Toll Free & 24/7 Available

Perforated Neoprene Sheet

Perforated Neoprene Technology

“Perforated” refers to precision-punching customized hole patterns into neoprene sponge to achieve:

✔ Enhanced Breathability – Promotes airflow & moisture management

✔ Weight Reduction – Up to 25% lighter than solid neoprene

✔ Design Versatility – Custom geometric patterns available

Processing Methods:

▸ Visible Perforation

• Fabric lamination → Precision punching

• Creates visible ventilation holes

▸ Hidden Perforation

• Sponge punching → Fabric overlay

• Maintains smooth appearance

Functional Applications:

• Ventilated wetsuit panels

• Breathable sports padding

• Lightweight medical braces

• Aesthetic footwear accents

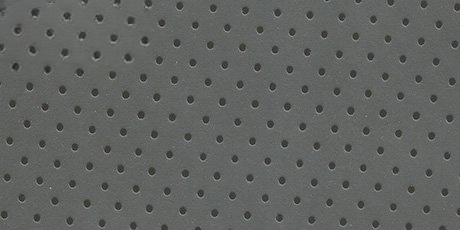

Visible Perforated Neoprene Fabric

Visible Perforated Neoprene

“Visible Perforated” refers to neoprene that is either:

• First laminated with fabric and then perforated, or

• Directly perforated without lamination

The result is a material with visible ventilation holes, offering:

✔ Enhanced Breathability – Improves airflow for comfort

✔ Reduced Weight – Up to 30% lighter than solid neoprene

✔ Flexible Design – Custom hole patterns (round, hexagonal, etc.)

Common Applications:

• Sports Gear – Ventilated knee/elbow pads

• Medical Use – Breathable orthopedic supports

• Equestrian Equipment – Lightweight horse leg wraps

• Technical Bags – Aerated back panels

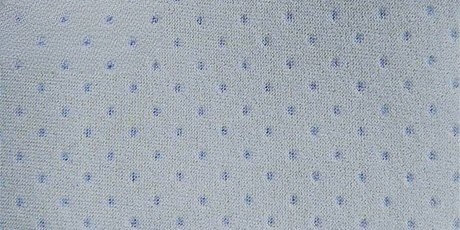

Inside Perforated Neoprene Fabric

Inside Perforated Neoprene

“Inside Perforated” refers to a specialized process where:

• The neoprene sponge core is first precision-perforated

• Then laminated with fabric on one or both sides

This creates a material with:

✔ Hidden Ventilation – Internal airflow channels (no visible holes)

✔ Weight Reduction – Up to 20% lighter than solid neoprene

✔ Reinforced Structure – 15% higher surface firmness

✔ Seamless Aesthetics – Perfect for visible outer layers

Technical Advantages:

• Maintains fabric’s original properties (stretch/abrasion resistance)

• Prevents water/sand intrusion (vs. visible perforation)

Premium Applications:

• Performance Apparel – High-end swimwear & fitness compression wear

• Medical Supports – Discreet orthopedic braces

• Equestrian Gear – Breathable saddle pads

• Tactical Bags – Lightweight yet structured compartments

Frequently Asked Questions

Are you a direct manufacturer?

Absolutely, we had our own cutting machine,embossing machine, lamination machine, die cut machine, warehouse, floor shop.We can also pick up you inspect us.

Can you do OEM for me?

Of course.Just telling me what you thinking or send some of pictures of your sample, we will make the products you need.

How do you control the products quality?

We creat professional QC team in each step, which well control your goods quality during all the mass production till shipping time.We can do inspection service for you.

Can you provide Free sample and return the sample fee to us?

Of course free provide, sample fee can be refund base on the quantity.

_副本.png)