- Welcome to Libaijia

Get Neoprene Solutions for Your Industry Needs

Whether you need high-performance materials for diving, surfing, water rescue, hunting and fishing or water sports applications, our Neoprene solutions deliver unmatched quality and reliability.

Need Help

Our teams are ready to assist you in selecting the perfect neoprene material for your specific application. Contact us today for technical support, samples, or customized solutions!

Mail us for any Queries

Shimen County, Changde city, Hunan Province

We Are Here Always

008618665359936

Chat with us anytime

008613317360392

Toll Free & 24/7 Available

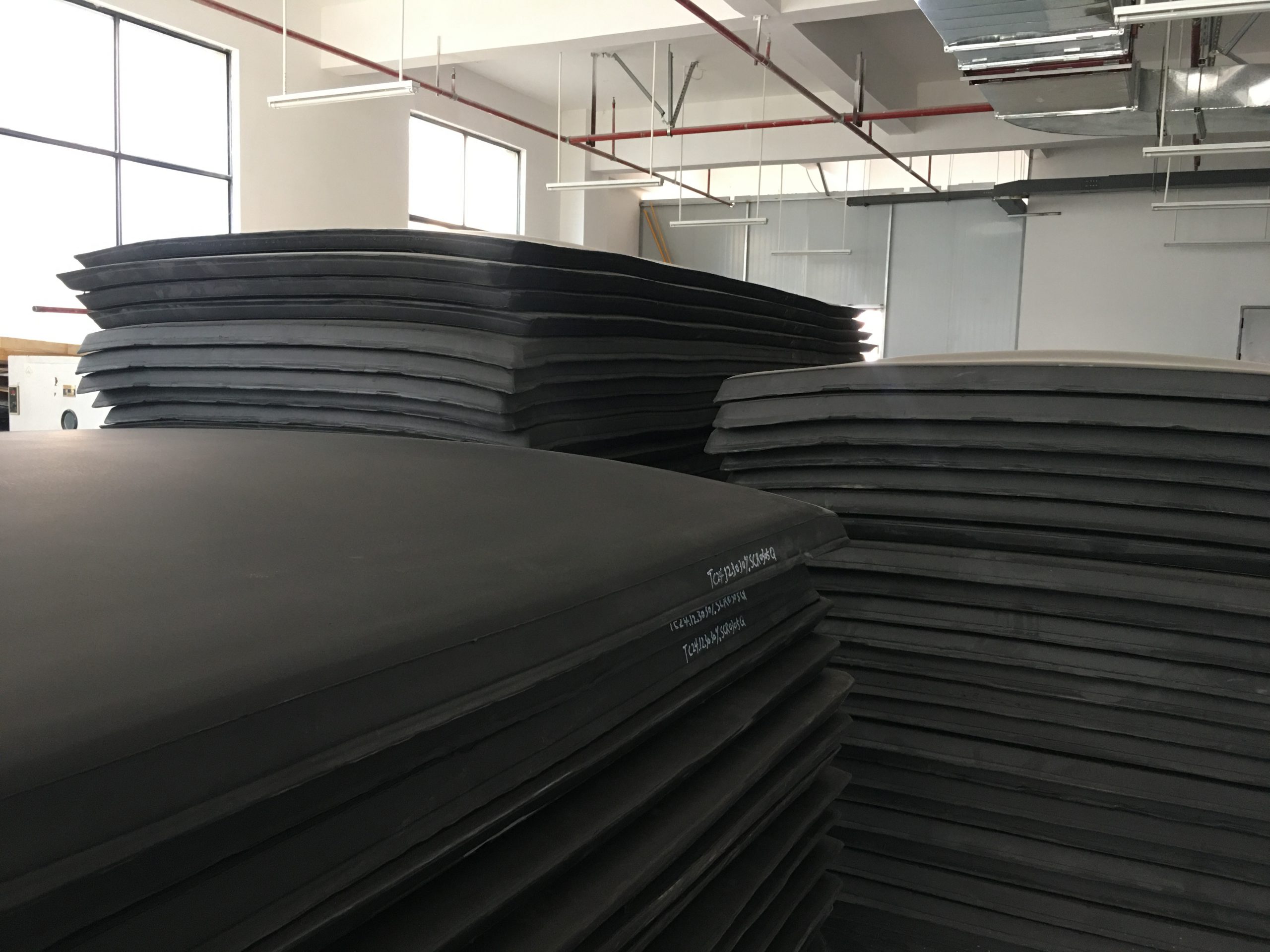

SBR Neoprene Sponge, Styrene Butadiene Rubber Sponge

SBR (Styrene Butadiene Rubber) is a petroleum-based synthetic elastomer polymerized from styrene and butadiene. Originally developed in the 1930s by Walter Bock of IG Farben AG as a tire material substitute for natural rubber.

By the 1950s-60s, American and Japanese manufacturers pioneered neoprene wetsuit production, later adopted by Korean, Taiwanese and Chinese makers. Wetsuit-grade neoprene features closed-cell foam (honeycomb structure), which is precisely calibrated for thickness and laminated with fabric layers (polyester/nylon/spandex).

SBR grade Neoprene: Made from styrene-butadiene rubber (commonly known as SBR, primarily produced domestically), it is suitable for the sports products market and is cost-effective, making it ideal for low-end wetsuits and protective gear.

Styrene Butadiene Rubber Sponge (SBR)

Explain: “SBR Neoprene Sponge” is a synthetic rubber produced by polymerization of styrene and butadiene. This is a low grade neoprene sponge.

Features: “SBR Neoprene Sponge” has excellent cushioning and warmth retention, but has poor compression resistance and is cheap.

SBR Applications:

-> 3°-5°: recreational wetsuit, diving gloves, diving socks, household products, protective gear

-> 7°-9°: cup sleeve, computer bags, protective cover

-> 12°-15°: vulcanized shoes

Color: Black, Cream

Frequently Asked Questions

Are you a direct manufacturer?

Absolutely, we had our own cutting machine,embossing machine, lamination machine, die cut machine, warehouse, floor shop.We can also pick up you inspect us.

Can you do OEM for me?

Of course.Just telling me what you thinking or send some of pictures of your sample, we will make the products you need.

How do you control the products quality?

We creat professional QC team in each step, which well control your goods quality during all the mass production till shipping time.We can do inspection service for you.

Can you provide Free sample and return the sample fee to us?

Of course free provide, sample fee can be refund base on the quantity.

_副本.png)